Page 3 - Campbell Fittings

P. 3

Campbell Coupling Selection Guide

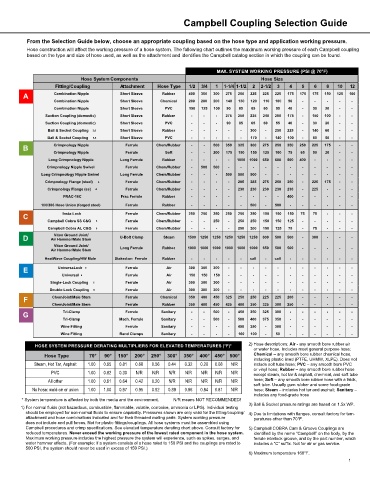

From the Selection Guide below, choose an appropriate coupling based on the hose type and application working pressure.

Hose construction will affect the working pressure of a hose system. The following chart outlines the maximum working pressure of each Campbell coupling

based on the type and size of hose used, as well as the attachment and identifies the Campbell catalog section in which the coupling can be found.

MAX. SYSTEM WORKING PRESSURE (PSI @ 70°F)

Hose System Components Hose Size

Fitting/Coupling Attachment Hose Type 1/2 3/4 1 1-1/4 1-1/2 2 2-1/2 3 4 5 6 8 10 12

A Combination Nipple Short Sleeve Rubber 400 350 300 275 250 225 225 225 175 175 175 150 125 100

Combination Nipple Short Sleeve Chemical 200 200 200 140 130 120 110 100 50 - - - - -

Combination Nipple Short Sleeve PVC 150 125 100 90 85 65 60 55 40 - 30 20 - -

Suction Coupling (domestic) Short Sleeve Rubber - - - 275 250 225 210 200 175 - 150 100 - -

Suction Coupling (domestic) Short Sleeve PVC - - - 90 85 65 60 55 40 - 30 20 - -

Ball & Socket Coupling 3,6 Short Sleeve Rubber - - - - - 300 - 250 225 - 140 60 - -

Ball & Socket Coupling 3,6 Short Sleeve PVC - - - - - 170 - 140 100 - 80 50 - -

B Crimpnology Nipple Ferrule Chem/Rubber - - 500 350 325 300 275 250 250 250 225 175 - -

Crimpnology Nipple Ferrule Soft - - 200 175 150 150 125 100 75 65 50 20 - -

• Tri-Clamp Fittings Long Crimpnology Nipple Long Ferrule Rubber - - - - 1000 1000 650 600 500 400 - - - -

• Tri-Clamp Adapters Crimpnology Nipple Swivel Ferrule Chem/Rubber - 500 500 - - - - - - - - - - -

• Machined Ferrules Long Crimpnology Nipple Swivel Long Ferrule Chem/Rubber - - - 500 500 500 - - - - - - - -

• Washdown Swivels Crimpnology Flange (steel) 4 Ferrule Chem/Rubber - - - - 285 285 275 250 250 - 225 175 - -

• PCT Couplings (Wine) Crimpnology Flange (ss) 4 Ferrule Chem/Rubber - - - - 230 230 230 230 230 - 225 - - -

• Wine Ferrules

FRAC-16C Frac Ferrule Rubber - - - - - - - - 400 - - - - -

100/206 Hose Union (forged steel) Ferrule Rubber - - - - - 500 - 500 - - - - - -

C Insta-Lock Ferrule Chem/Rubber 250 250 250 250 250 250 150 150 150 75 75 - - -

Campbell Cobra SS C&G 5 Ferrule Chem/Rubber - - 250 - 250 250 150 150 125 - - - - -

Campbell Cobra AL C&G 5 Ferrule Chem/Rubber - - - - 250 200 150 125 75 - 75 - - -

Viton Ground Joint/

D Air Hammer/Male Stem U-Bolt Clamp Steam 1500 1250 1250 1250 1250 1250 800 500 500 - 300 - - -

Viton Ground Joint/ Long Ferrule Rubber 1000 1000 1000 1000 1000 1000 650 500 500 - - - - -

Air Hammer/Male Stem

HeatWave Coupling/HW Male Staked-on Ferrule Rubber - - - - - call - call - - - - - -

E UniversaLock 6 Ferrule Air 300 300 300 - - - - - - - - - - -

Universal 6 Ferrule Air 150 150 150 - - - - - - - - - - -

Single-Lock Coupling 6 Ferrule Air 300 300 300 - - - - - - - - - - -

Double-Lock Coupling 6 Ferrule Air 300 300 300 - - - - - - - - - - -

F ChemJoint/Male Stem Ferrule Chemical 350 400 450 325 250 250 225 225 200 - - - - -

ChemJoint/Male Stem Ferrule Rubber 350 400 450 425 400 350 325 300 250 - - - - -

G Tri-Clamp Ferrule Sanitary - - 500 - 450 350 325 300 - - - - - -

Tri-Clamp Mach. Ferrule Sanitary - - 500 - 500 400 375 350 - - - - - -

Wine Fitting Ferrule Sanitary - - - - 450 350 - 300 - - - - - -

Wine Fitting Band Clamps Sanitary - - - - 100 100 - 50 - - - - - -

HOSE SYSTEM PRESSURE DERATING MULTIPLIERS FOR ELEVATED TEMPERATURES (°F)* 2) Hose descriptions: Air - any smooth bore rubber air

or water hose. Includes most general purpose hose;

Hose Type 70° 90° 150° 200° 250° 300° 350° 400° 450° 500° Chemical – any smooth bore rubber chemical hose,

including plastic lined (PTFE, UHMW, XLPE). Does not

Steam, Hot Tar, Asphalt 1.00 0.95 0.81 0.68 0.56 0.44 0.32 0.20 0.08 N/R include soft tube hose; PVC – any smooth bore PVC

or vinyl hose; Rubber – any smooth bore rubber hose

PVC 1.00 0.82 0.30 N/R N/R N/R N/R N/R N/R N/R except steam, hot tar & asphalt, chemical, and soft tube

All other 1.00 0.91 0.64 0.42 0.20 N/R N/R N/R N/R N/R hose; Soft – any smooth bore rubber hose with a thick,

soft tube. Usually gum rubber and some food-grade

No hose: weld-on or union 1.00 1.00 0.97 0.95 0.92 0.89 0.86 0.84 0.81 N/R hose; Steam – includes hot tar and asphalt; Sanitary –

includes any food-grade hose

* System temperature is affected by both the media and the environment. N/R means NOT RECOMMENDED!

1) For normal fluids (not hazardous, combustible, flammable, volatile, corrosive, ammonia or LPG). Individual testing 3) Ball & Socket pressure ratings are based on 1.5x WP.

should be employed for non-normal fluids to ensure capability. Pressures shown are only valid for the fitting/coupling/ 4) Due to limitations with flanges, consult factory for tem-

attachment and hose combinations indicated and for their threaded mating parts. System working pressure peratures other than 70°F.

does not include end pull forces. Not for plastic fittings/couplings. All hose systems must be assembled using

Campbell procedures and crimp specifications. See elevated temperature derating chart above. Consult factory for 5) Campbell COBRA Cam & Groove Couplings are

reduced temperatures. Never exceed the working pressure of the lowest rated component in the hose system. identified by the name “Campbell” on the body, by the

Maximum working pressure includes the highest pressure the system will experience, such as spikes, surges, and ferrule interlock groove, and by the part number, which

water hammer effects. (For example: If a system consists of a hose rated to 150 PSI and the couplings are rated to includes a “C” suffix. Not for air or gas service.

500 PSI, the system should never be used in excess of 150 PSI.)

6) Maximum temperature 160°F.

1